Energy consumption in refrigerated vending isn’t discretionary spending. It’s tribute paid to the Second Law of Thermodynamics. Every kilowatt-hour on your utility bill represents heat that forced its way through inadequate insulation or was wasted by an inefficient compressor fighting a losing battle against entropy.

Traditional vending machines consume 2,500-4,400 kWh annually—roughly $200-350 per machine at average commercial rates. Smart coolers with superior insulation and variable-speed compressors operate at 30-55% lower consumption. The difference isn’t better technology. It’s better physics compliance.

You don’t optimize energy costs. You audit the subsidy you’re paying to thermal inefficiency and calculate whether continuing to fund it remains cheaper than capitulation.

The fundamental question isn’t “how much energy does my machine use?” It’s “how much am I paying physics because my equipment surrendered to heat flow instead of resisting it?”

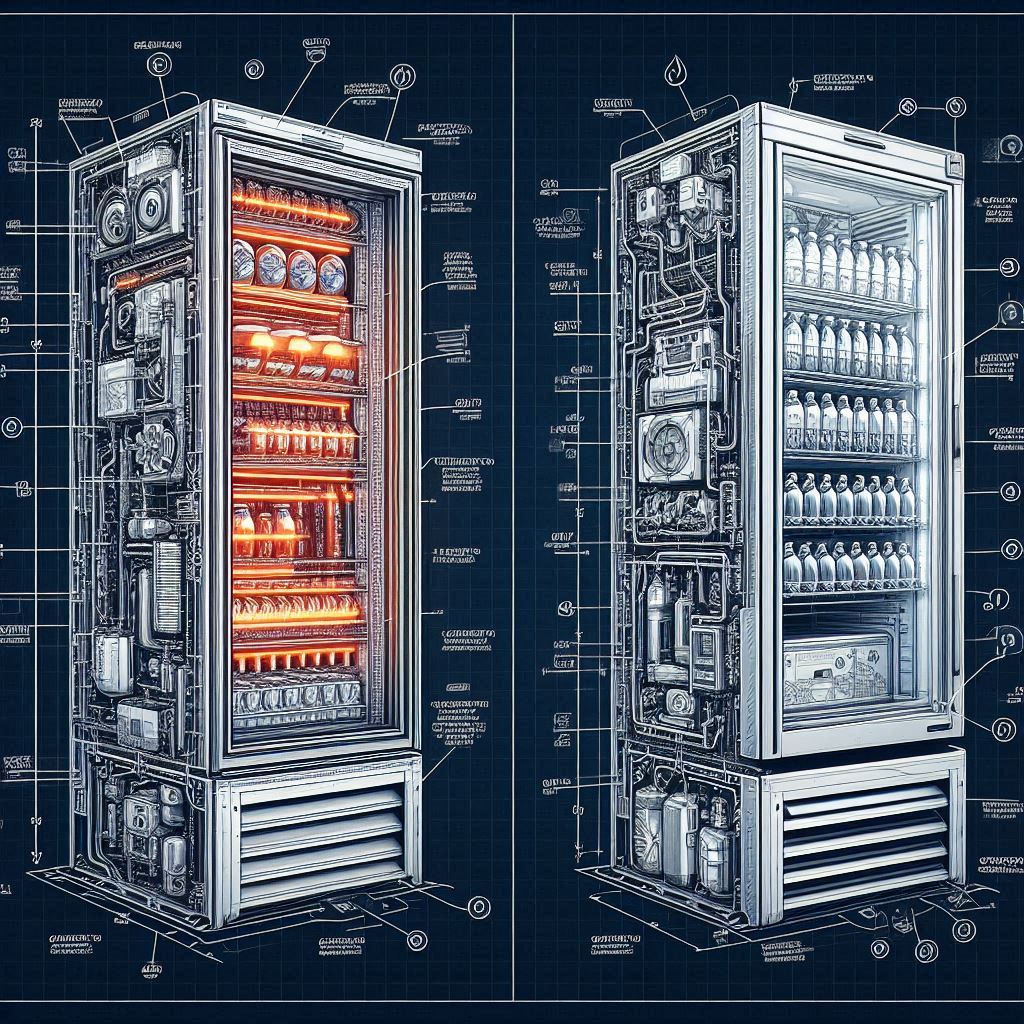

Insulation R-value quantifies thermal resistance—how effectively a barrier prevents heat transfer. Higher R-values mean less heat penetration, which means less compressor runtime, which means lower energy tribute. The mathematics are unforgiving.

Standard commercial refrigeration operates at R-25. Walk-in coolers require minimum R-30. High-performance systems achieve R-32 or higher using advanced polyurethane foam that reduces thermal conductivity by 50%.

Traditional vending machines typically deploy R-15 to R-20 insulation. This isn’t a feature gap. It’s a structural decision to subsidize higher energy consumption in exchange for lower upfront equipment costs.

The compounding effect is brutal:

A machine rated at R-18 might functionally operate at R-12 after installation flaws and material aging. That’s the difference between paying physics $280 annually versus $420—a $140 perpetual tax on thermal surrender.

Coefficient of Performance (COP) measures refrigeration efficiency: how many units of cooling you extract per unit of electrical work consumed. Modern refrigeration systems achieve COP values of 2.5-3.5, meaning they move 2.5-3.5 times more heat than the electrical energy they consume.

But COP collapses as temperature differential increases. The formula is stark:

COP = T_cold / (T_hot – T_cold)

Maintain a machine at 38°F in a 75°F environment, and you’re fighting a 37°F differential. Place that same machine outdoors in direct sun at 95°F, and the differential jumps to 57°F. For every 10°F increase in ambient temperature, energy consumption rises 8-12%.

This isn’t linear scaling. It’s exponential collapse.

Traditional machines respond with fixed-speed compressors running binary on/off cycles. Smart coolers deploy variable-speed compressors that modulate output to match cooling demand. The efficiency advantage compounds:

A National Renewable Energy Laboratory study measured daily consumption of 7-11 kWh for traditional machines. Adding load management (occupancy sensors) dropped this to 5.6 kWh—a 33% reduction. Combining load management with LED lighting achieved 3.7 kWh daily—55% total reduction.

The energy isn’t being saved. The thermal resistance hierarchy is being enforced.

Placement determines the temperature differential your compressor must overcome. This isn’t a location decision. It’s a physics tax rate selection.

Indoor placement (climate-controlled):

Indoor placement (unconditioned space):

Outdoor placement (shaded):

Outdoor placement (direct sun):

Outdoor machines consume 20-35% more electricity than indoor units due to temperature fluctuations and weather exposure. But the real cost isn’t the immediate energy premium. It’s the accelerated component failure from sustained high-duty-cycle operation.

A compressor rated for 40% duty cycle that operates at 75% duty cycle will experience premature failure—often within 3-5 years instead of 8-12. The energy subsidy you’re paying to physics includes not just electricity, but accelerated capital depreciation.

What percentage of your machines are placed where physics taxes them most heavily?

Energy bills are visible. Maintenance costs triggered by thermal stress are not.

Research from Unity Cooling Systems documented a supermarket walk-in cooler with degraded insulation experiencing:

After upgrading to R-30 insulation (30% energy reduction), the facility dropped to one minor breakdown annually at $500, eliminated spoilage, and saved $17,900 yearly—a 95% reduction in thermal inefficiency costs.

The energy consumption was the symptom. The inadequate thermal resistance was the disease.

Traditional operators see $300 annual electricity costs per machine and accept them as fixed. Sophisticated operators see a $300 signal that the compressor is fighting a losing thermal battle—and calculate how long until the war costs more than surrender.

Smart coolers don’t “save energy.” They enforce superior thermal discipline through:

The cumulative effect: Energy Star certified machines consume 1,000 kWh less annually than standard models—approximately 35-40% energy reduction.

At $0.13/kWh commercial rate:

Across a 50-machine route: $8,450 annual energy subsidy eliminated.

Over 10-year equipment lifespan: $84,500 total physics tax avoided.

This excludes maintenance cost reduction from lower compressor stress, extended component lifespan, and reduced service calls. The energy cost is the visible fraction. The thermal efficiency dividend extends across the entire operational chain.

How many machines would you need to replace before the eliminated physics tax exceeds your annual equipment depreciation budget?

Smart operators don’t accept manufacturer energy ratings. They audit actual thermal performance.

Diagnostic protocol:

One operator documented precise heat gain measurements: 1.16 watts continuous transfer through a DIY cooler versus theoretical 3.9 watts with degraded insulation—a 70% thermal efficiency variance based purely on R-value execution.

The machines that cost you most aren’t the ones consuming the most energy today. They’re the ones with the steepest thermal resistance decay curves—the units where your subsidy to physics is accelerating.

Catalog your existing fleet by:

Calculate your baseline physics tax: Total annual kWh × local electricity rate = annual thermal tribute.

Rank machines by combined thermal inefficiency score:

The top 20% of machines on this list represent your highest subsidy to physics. These are replacement priority targets.

For top 20% thermal failures, calculate:

Break-even occurs when avoided physics tax exceeds equipment price differential. Post-break-even, every operating year is pure thermal efficiency dividend.

Replace machines in order of:

Do not replace all machines simultaneously. Thermal efficiency optimization follows the Pareto principle: 20% of your fleet likely represents 50-60% of total thermal inefficiency costs.

Install consumption monitoring on all machines. Track:

Any machine showing >15% consumption increase year-over-year without seasonal explanation signals thermal resistance degradation. Don’t wait for catastrophic failure. Thermal efficiency decay is a leading indicator of imminent component breakdown.

Energy costs in refrigerated vending aren’t negotiable with the utility company. They’re negotiated with thermodynamics—through insulation R-value, compressor efficiency, and temperature differential management.

Traditional operators accept their utility bills as fixed costs. Sophisticated operators recognize them as thermal resistance scorecards.

The machines that cost you most aren’t the ones with the highest energy consumption. They’re the ones where your subsidy to physics is accelerating—where thermal resistance is degrading, compressor duty cycles are climbing, and the tax rate you pay to entropy is compounding.

You can’t eliminate the Second Law of Thermodynamics. But you can stop funding its enforcement against you.

If you want to know more about the advantages of smart coolers over traditional machines, here is my post on that: Smart Coolers vs Traditional Vending